|

Ivor Tseng, Scientist at R&D Division, Moldex3D |

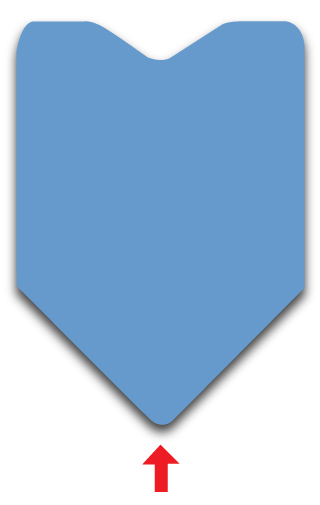

Injection molding is the most common manufacturing process for producing plastic parts. Though the molding technology is well-developed, there is a long-running problem requiring an urgent solution for the industry: to date, prior state-of-the-art predictive engineering tools have always provided unsatisfactory results regarding “so-called ear-flowâ€, in which the advance of the flow front in the center of the cavity is obviously slower than at the edges, as shown in Fig. 1. Not all polymers have consistently yielded the ear-flow. The effect of part thickness on the flow is clearly seen for certain polymers. The ear-flow is observed notably in thin parts but has not been seen in thicker parts. A faster injection rate easily results in ear-flow in contrast to a slower injection rate. These phenomena are urgently needed to be clarified by CAE technology for the industry.

Fig. 1 Schematic of ear-flow

The past flow simulation only considers the sheer effects. However, the real flow behavior is the comprehensive effects of sheer and extension effects. Thus, the Moldex3D R&D team has been committed to developing a new viscosity model, called the eXtended GNF (GNF-X) model, through which the weighted viscosity with the coexistence of shear and extensional flow can be derived. Thus, the primary objective of this work is to simulate a reliable Ear-flow for neat polycarbonate (PC) material in an injection molded disk via a new Moldex3D Flow solver coupled with the GNF-X equation [U. S. Patent Pending in USPTO with Application No. 62/886,539 (2019)].

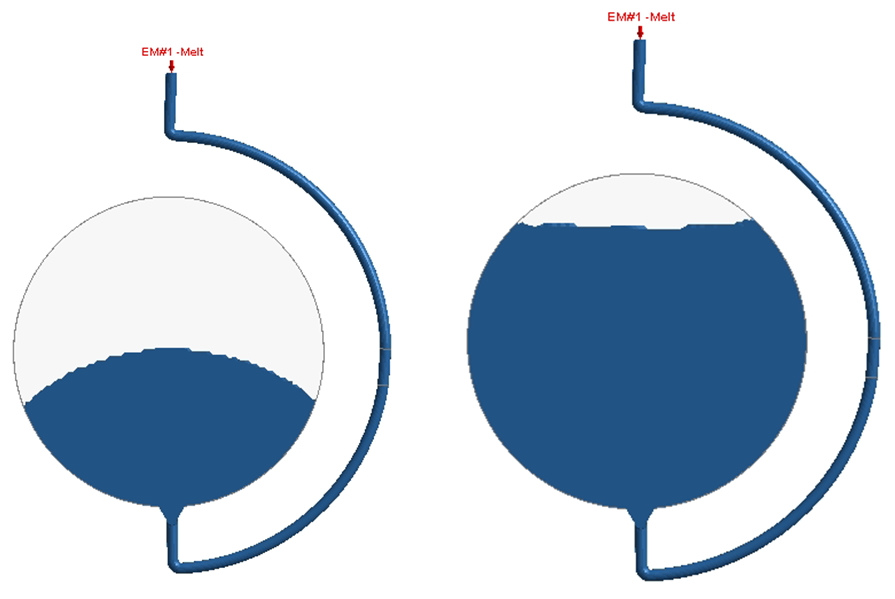

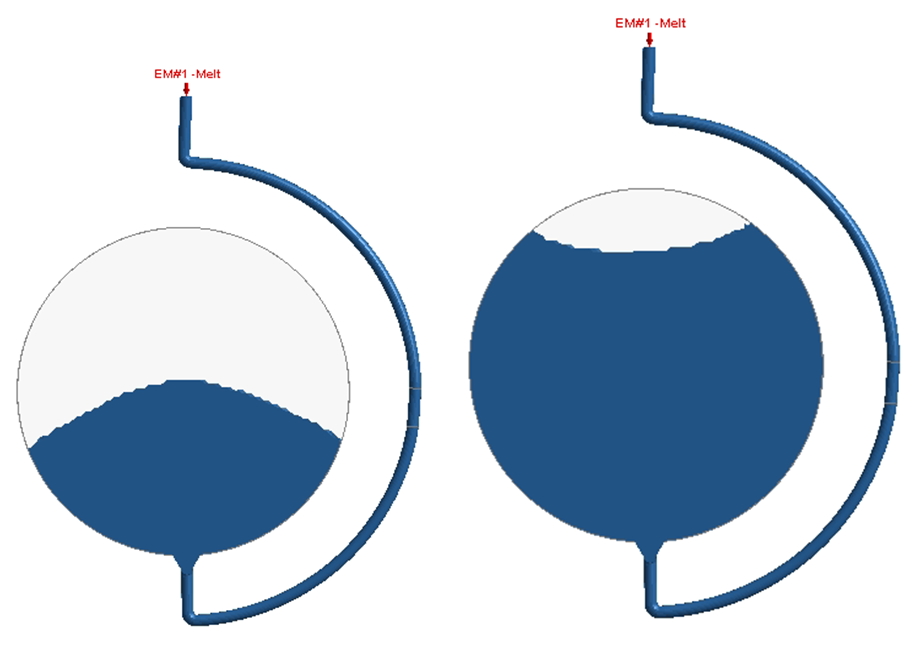

In this work, the primary objective is to simulate the ear-flow in injection molding via a new viscoelastic model, as compared with the GNF viscosity model. Referring to the work of Beaumon [14], a practical injection mold filling simulation of the polycarbonate (PC) fluid for the disk cavity was performed by the commercial injection molding simulation software, Moldex3D. The melt temperature and mold temperature are 293.3 oC and 82.2 oC, respectively. The injection time is 1.0 seconds. Using the cross model of the GNF shear viscosity, Fig. 2 shows the concave front at 50%-filled cavity and the flat front at 90%-filled cavity. This is not consistent with the real-world status. Next, the new GNF-X model with the extension viscosity is used in the Moldex3D flow computation. Significantly, Fig. 3 exhibits the advancement of the flow front in the centre of the cavity is significantly slower than at the edges, namely, so-called “ear-flowâ€. Such a prediction is satisfactory and validates that Moldex3D’s new extension viscosity function can successfully resolve a long-running problem of ear-flow simulation.

Fig. 2 Injection molded disk simulation using the GNF shear viscosity model for PC

Fig. 3 Injection molded disk simulation using the new GNF-X viscoelastic model for PC

Herringbone Pulley,Herringbone Belt,Drive Belt Pulley,Belt Conveyor Drive Pulley

NINGBO TANSUO MACHINE MANUFACTURING CO., LTD. , https://www.tsjxidler.com