|

Pierre Yeh, Engineer at Technical Support Team, Moldex3D |

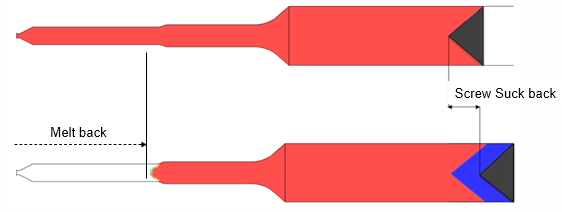

Suck back is the action of the screw moving backward but not rotating after reaching the metering position. Since the screw does not rotate, no extra melt will be delivered to the nozzle and metering zone. The process is shown in the figure below. After the suck back, the barrel will create additional space in the blue area. At this time, the melt at the nozzle tip will be moved backward, and meanwhile, the pressure will drop, causing the specific volume of the melt to increase. The volume will also become larger, occupying the space created after the suck back.

Moldex3D simulation of the filling stage can now incorporate the suck back behaviors in its barrel analysis. Thus, the filling time, screw position, and injection volume can be more accurately predicted.

Operating Procedures

Limitation

- Only Injection Molding (IM) process is supported.

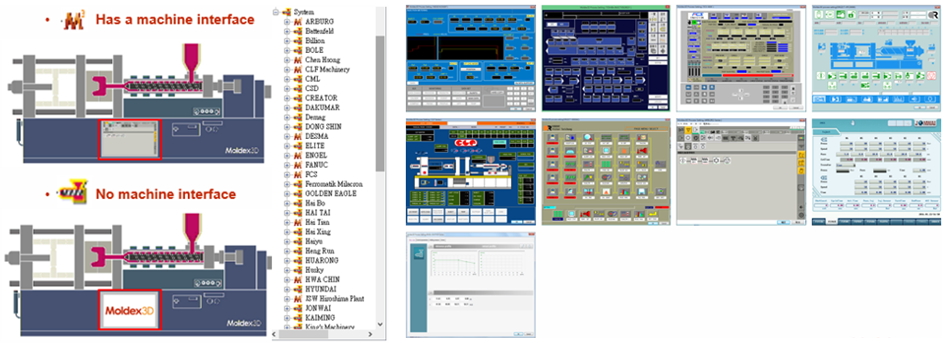

- The suck back setting is only supported in the machine mode through the real machine interface.

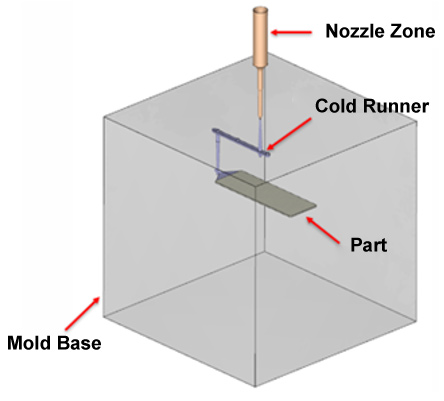

- The attributions of the nozzle and metering zone need to be set as “Nozzle Zoneâ€.

- The suck back simulation is not supported in the model with the “Hot Runner†attributions.

Step 1: Model preparation

After launching Moldex3D Studio (2021), create or import a mesh model containing the part, cold runner, cooling system, and nozzle zone.

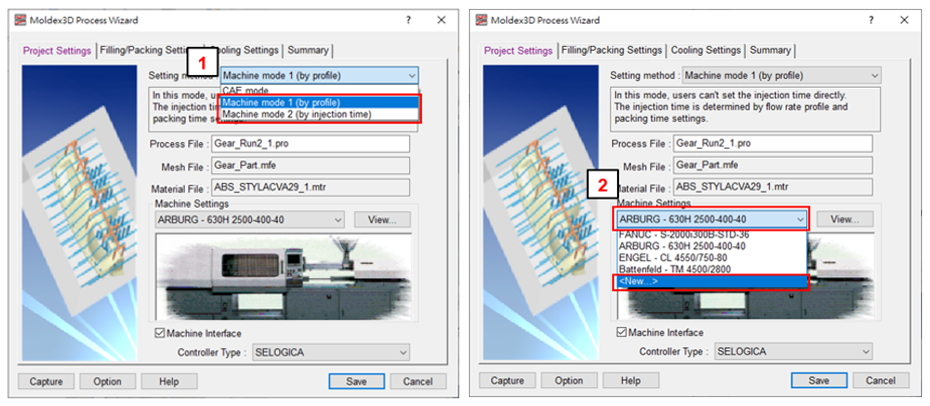

Step 2: Machine mode settings and machine selection

Select “Machine Mode†after opening the Process Wizard, select “New†in the machine settings, and select an injection machine in the machine database.

Note: When selecting a machine, please note that if the real machine interface is supported or not. (Currently, more than 20 machines are supported.)

Step 3: Suck back settings

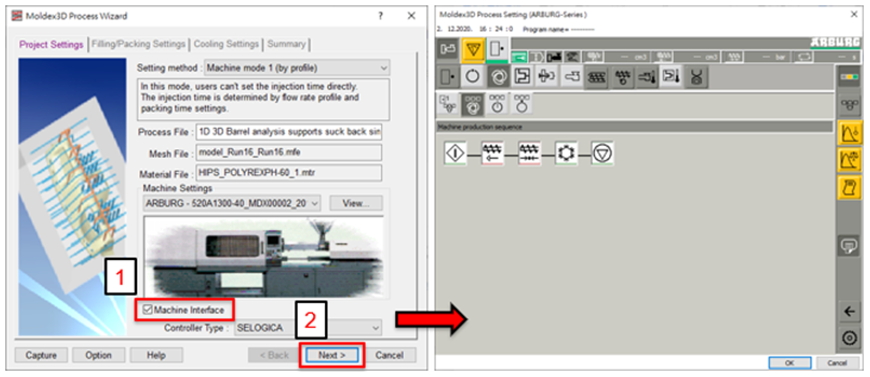

1. After selecting an injection machine with a machine interface supported, check the “Machine Interface†and select the controller type, and then click “Next†to display the real machine interface.

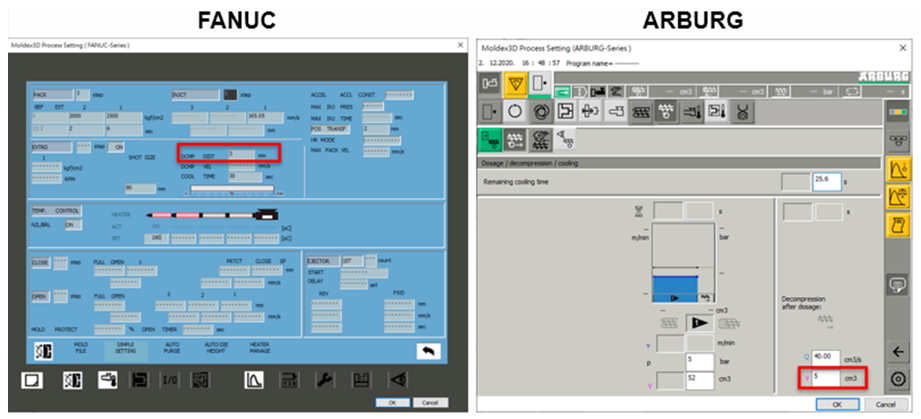

2. Find the suck back parameters in the machine interface and input its suck back distance or volume.

Step 4: Result

1. Screw position vs. injection pressure

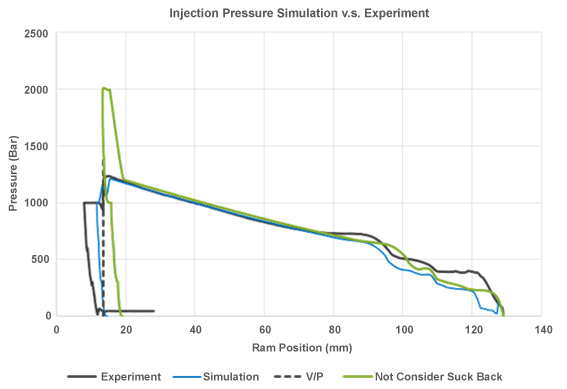

As shown in the figure below, without considering the suck back (the green line), the injection pressure will rise because the mold is filled, but the screw has not reached the VP switching point. When the suck back behavior is considered (blue line), the pressure and VP position results are much closer to the experiment.

2. Flow patterns

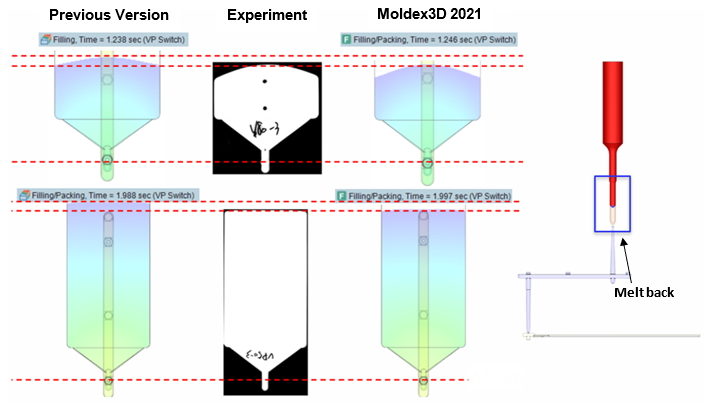

When the VP position reaches 80mm and 50mm, compared with the experiment, it can also be observed that the simulated flow front is closer to the experiment when the suck back behaviors are considered.

Chemical packaging,Powder packaging,Packing machine,Food packaging machine,Packaging equipment

AGILOR , https://www.agilorpackage.com