Cloud Tsai, Manager at Product Division, Moldex3D

The molding simulation pre-processing of a complicated geometry is usually time-consuming. The reasons are as below:

- From the design factory, mold factory, outsourcing manufacturer, and assembly factory, the geometry files will be exported by different CAD software. These geometry files submitted to the customers thus have been transferred many times, which can cause geometric defects.

- Besides geometric defects, the complicated geometric features can also cause meshing issues such as sharp and sliver fillet elements. Lots of effort will then be required to avoid poor mesh quality and failure in molding simulation.

- Complicated runners or cooling channels are used in some precise mold designs to enhance the success rate and product quality. These runner and cooling channel designs cannot be simulated through beam elements created in pre-processing, so their geometric models should be used in simulation.

Normally, while facing the issues mentioned above, users have to modify the geometry, mesh, or the cooling channel layout to meet the requirements of mesh establishing, such as having the inlet and outlet closely fitted to the cavity. This pre-processing will cost lots of time for results in a mesh file suitable for simulation.

To reduce users’ loading in pre-processing, Moldex3D Studio has continuously enhanced the pre-processing workflow and provided many pre-processing tools for users to process product geometry and mesh more efficiently. The major tools are introduced below.

Geometry fixing

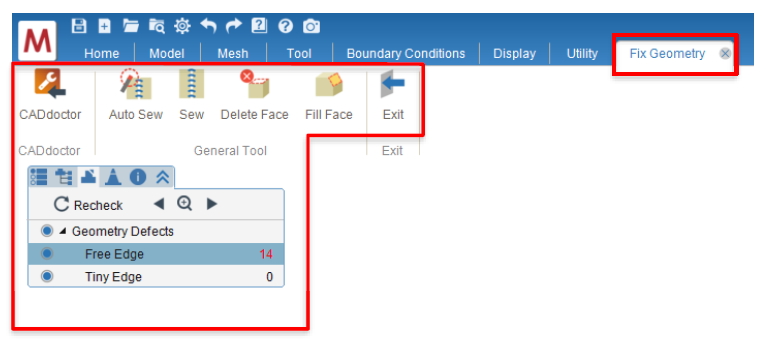

The geometry fixing tools in the new Fix Geometry Tab and Geometry Defect Tree can simplify the geometry processing workflow.

Fig. 1 New fix geometry ribbon, geometry defect tree, and CAD functions

Auto Sew and Sew

Moldex3D 2020 provides two Sew tools. Auto Sew is the original tool to sew the geometry free edges in the whole area with a user-defined tolerance value. The new Sew feature enables users to sew on the specific edges, so the free edges at different locations can be sewn with different tolerances.

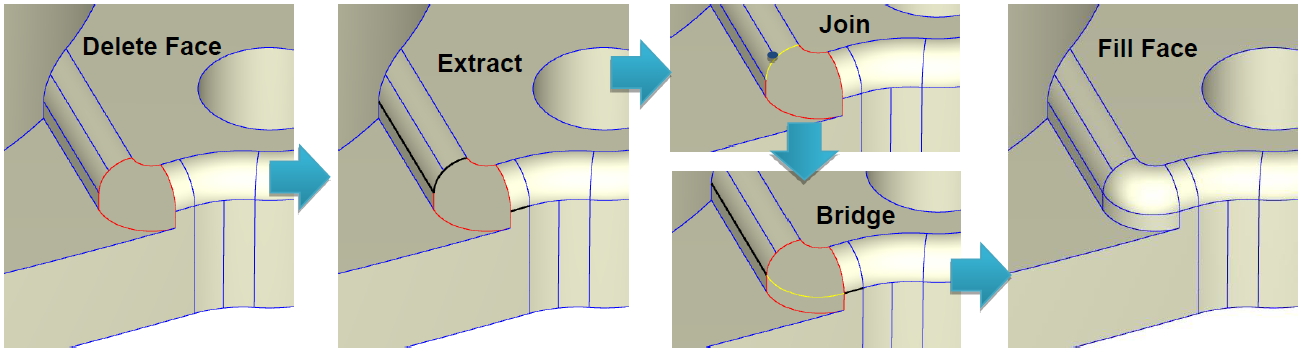

Delete Face and Fill Face

To rebuild a bad geometry surface with a better-quality curved face, Moldex3D provides the Delete Face and Fill Face features for users. When using Fill Face to build a new face, users have to select the curves or geometry edges (normally 2 to 4 edges). Thus, Moldex3D Studio also provides more tools for curves, including Extract Edge Curve, Join Curve, and Bridge Curve in Tool ribbon, assisting users to deal with the curve data and build curve surfaces.

An example is shown in Fig. 2, when a fillet face has defects, users can delete it first. The free edge amount then is over 4, so one can use extract edge curves and join them for one edge and bridge between two edges for another. Use Fill Face in the end to rebuild the curved face.

Fig. 2 An application of the new CAD tools

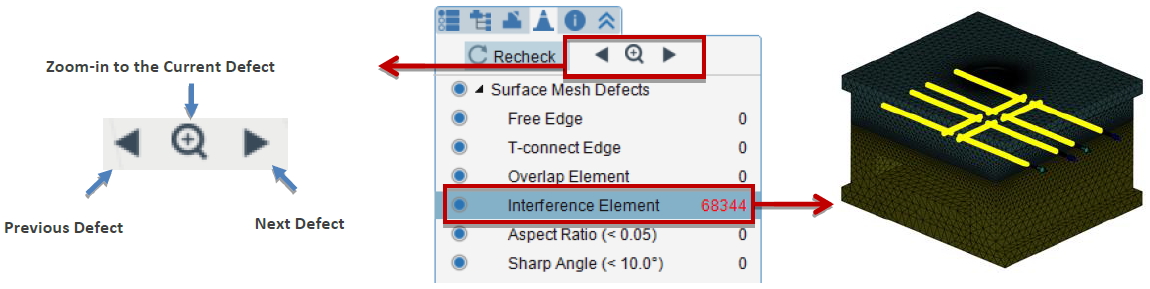

The geometry & mesh defect navigator

The new navigator (Fig. 3 left) in Geometry Defect Tree and Mesh Defect Tree can quickly switch between different defects and zoom in the defect locations. When the mesh element amount of a complicated geometry is large, this function can help users quickly find the defect locations and fix them.

Moldex3D Studio added the surface mesh interference check function. This tool will mark serious surface mesh interference as an error, and users have to confirm and fix the mesh interference first so that they continue building solid mesh. As shown in Fig. 3 (right), if there is no space on the mold plate for cooling channels and causes severe interference, the issue will be detected on the Mesh Defect Tree.

Fig. 3 Mesh defect browser in Defect Tree and interference check in Mesh Defect Tree

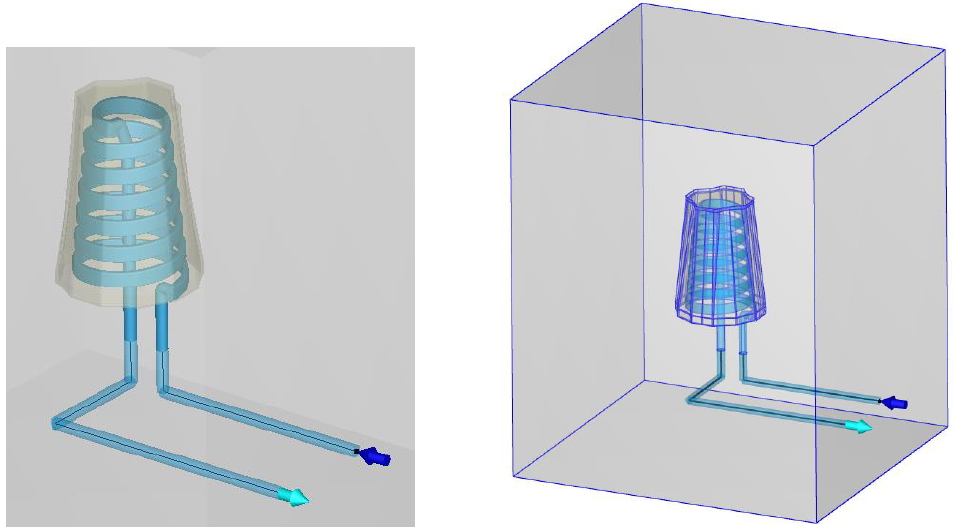

Moldex3D Studio supports mixed cooling channels of line-defined and geometry objects. Users can use the geometry channels to simulate complicated cooling channel designs and use beam elements allowing convenient design change for others. For example, users can adjust the outlet and inlet to fit closely to the cavity so that mold base mesh can be generated accurately.  Â

Fig. 4 Moldex3D Studio supports curve and geometry mixed cooling channel

Moreover, Moldex3D Studio has enhanced many functions for the cooling channel, including organizing and displaying cooling channel loop in groups and to display major defects with adjusted channel checking items. The feature of the automatic assignment of inlet and outlet was also enhanced.

Moldex3D Studio 2020 provides multiple pre-processing tools for users to process complicated geometry and mesh more efficiently. Adding new fix geometry tools for multiple curves and curved surface; providing geometric and mesh defect navigator to quickly locate issues, enhancing cooling channel features by supporting mixed cooling channels; automatically organizing cooling channel loop in groups and assign inlet and outlet. With upgraded Moldex3D pre-processing capabilities, it assists customers with more efficiency to deal with the mesh establishment of complicated products and reducing time and effort costs.

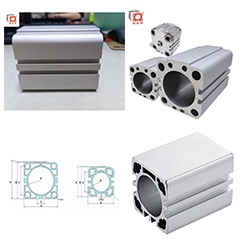

ADVU/ADVV Pneumatic Cylinder Barrel

ADVU double-acting Compact Air Cylinder

AEVU single-acting push type Compact Air Cylinder

AEVUD single-acting pull type Compact Pneumatic Cylinder

ADW compa Preamaic 0yinder compae m s052 S aad o tes a ompadAr c me ste are tasaessa mms d te st tpe ftre atehe tan m peameseotigem

Bore Sizes: 16.25.32.40,50.63,80.100

Stroke Lengths: 5,10,15,20,25,30,35,40,45,50,75,100,200,300mm Pneumatic Cylinder Tube

Operating Pressure: 0.13-1.0 MPa

Speed:30-800mm/s;

Working Environment Temperature: -10 to 80°C

The ADVU cylinder is a compact cylinder produced by the German company Festo, known for its small size and high efficiency. The ADVU series is typically classified as thin or compact cylinders, suitable for applications with limited space.

Here are some characteristics and specifications of Festo ADVU cylinders:

Integrated design:

The motor is usually integrated with the cylinder body.

The controller and cables are also part of the system.

Installation and adjustment:

The installation position of the magnetic switch is reserved on the surface of the cylinder block, which makes it very easy to install and adjust the position of the magnetic switch.

Model and size:

The ADVU series offers a variety of sizes to choose from, such as 12, 16, 20, 40, 50, 63, and other models with different cylinder diameters.

Different travel lengths are available for selection to meet different application requirements.

Technical parameters:

The diameter of the piston can vary depending on the model.

The length of the trip will also vary depending on the specific model.

The buffering type is generally an elastic buffering ring/pad at both ends.

The installation position is flexible and can be installed in different directions.

The operating mode is usually double acting, meaning that the piston can be pushed in two directions by compressed air.

Application areas:

Due to its compact design, ADVU cylinders are commonly used in automated equipment that requires space saving, such as packaging machinery, electronic assembly lines, etc.

ADVU/ADVV Pneumatic Cylinder Barrel,ADVU Pneumatic Cylinder Barrel,ADVV Pneumatic Cylinder Barrel,ADVU Pneumatic Cylinder Tube

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com